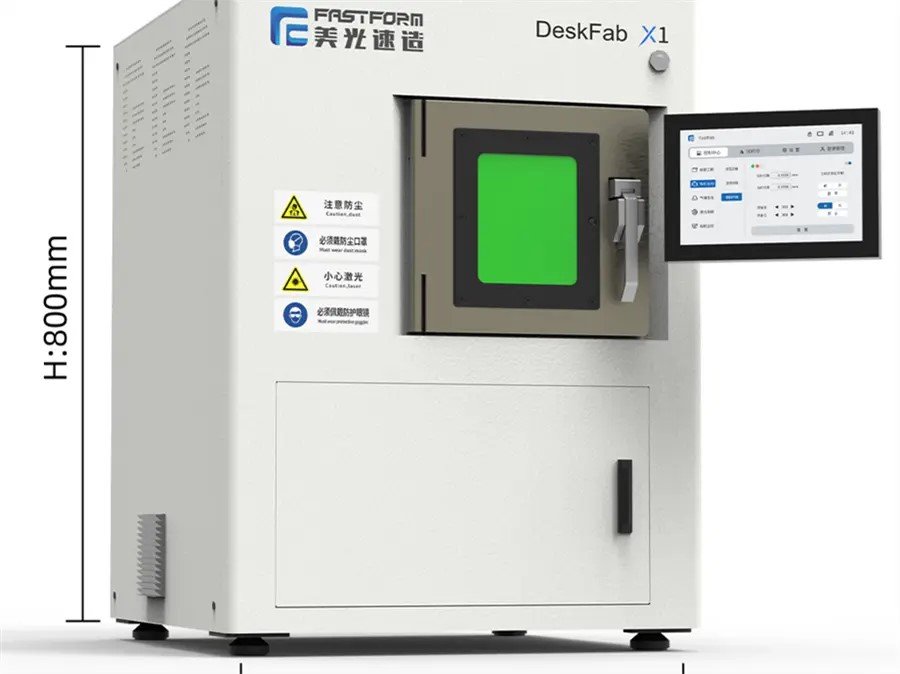

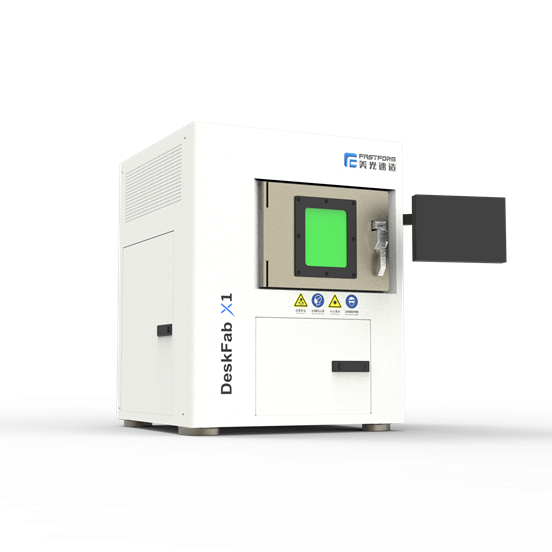

DeskFab X1 All in One Desktop Metal 3D Printer

Printer specifications

| Item | Specification |

| Printer Model | DeskFab X1 |

| Dimensions | 650mm×640mm×800mm(W×D×H) |

| Weight | 120kg |

| Building Size | Ø100×80mm(Baseplate included) |

| Spot Size | 50-80um |

| Laser Power | 300W |

| Min. Oxygen | ≤100ppm |

| Scan Speed | 7m/s |

| Layer Thickness | 20-150um |

| Laser Source | Single |

| Laser Type | CW Fiber Laser |

| Recoating Type | Upper feeding & One-way recoating |

| Printing Accuracy | ±50μm |

| Powder Capacity | 1.6L |

| Power Failure | Auto Resume |

| Recoater Type | Soft Blade Recoater |

| Baseplate Fixing Type | Magnetic Fixed |

| Filtration System | Permanent Filter ≥30k Hours |

| Typesetting Mode | Automatic Typesetting &Path Planning |

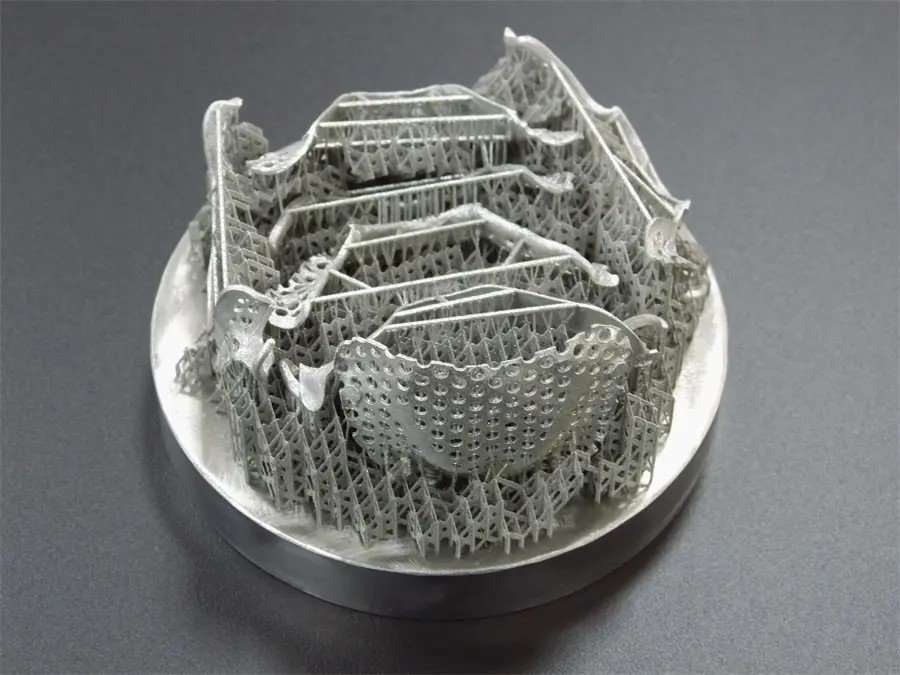

| Printable Material | CoCr, Titanium Alloy, Pure Titanium |

| Softare System | FastLayer Splicing Software & FastFab Operation Software |

| Cooling Type | Water-Cooled |

| Ambinent Temperature | 15~28℃ |

| Ambinent Humidity | ≤78% |

| Power Input | 220V AC, Single Phase |

| Average Power Output | 1kW |

| Protective Gas | N2, Ar |

Fastlayer Slicing software

After 8 years of independent research and development, the 3D slicing software is automatically programmed for dental and industrial precision design.

Use one-click to complete typesetting and plan paths. Customize the size of the printing platform and criticize any model.

Suitable for all kinds of 3D printing files: STL, OBJ, CAD ,STEP, 3MF.

Integrate the printing parameter database of various metal materials, self-developed precision parameter library for dental cobalt-chrome alloy and titanium alloy, and provide customers with independent development and customized parameter functions

Available for CoCr, Titanium, Stainless steel, Aluminum, etc. Metal powders

Layer thickness range from 20um -100um

FastFab 3D Printing control Software

Simply user interface , logical and organized layout with various tools and functionalities

Easy to use , the software's streamlined workflow and straightforward controls make it effortless for users to get started and accomplish their tasks.

software's performance and responsiveness contribute to a seamless and uninterrupted user experience.

The software can be easily operated in 5-10 minutes

All the operation process is done step by step, there will be no logical errors, and the time and print quality will be saved

Camera integrated to help operator easy to monitoring printing process and without risks from Laser radiation

Printing logs will record all printing process data and easy to check all printing program

Help service to analyze and troubleshooting to improve the metal powder printing quality.

Accessories and spare parts

1) Cleaning Kit

2) Silicon recoater blade

3) Hardware hand tools

4) CoCr/Titanium baseplate

5) Other necessary tools and accessories.

FAQ

1. Your main products are those?

Our main products are industrial SLM 3D printer,,Detal 3D printer,Customized Jewerly Printer, Customized 3D Printing Service.

2. How about quality control in your factory?

We have a pre-shipment inspection team, every machine goes through at least automatic running over 72 hours before shipment.

3. Why choose us?

We are a professional and full solution provider of dental printing, including 3d printers, printing and design service of crowns and frameworks to cover all your needs. And we have our 24 hours online after-sales team to solve all of your problems.

4. Can I customize the product?

Abosolutely,We are very professional in the dental feild, industrial Mold and very confident to customize the printer for you according to your requirements if our existing machines can not meet your needs

More Images